This group covers a broad range of technologies, from classical processing techniques (e.g., injection molding, compression molding, extrusion) to compounding and foaming (physical and chemical). Furthermore, novel technologies (e.g., additive manufacturing) are used to achieve system and function integration of polymers and elastomers. Research work focuses on the flow behavior of polymers, the reduction of process energy and the optimization of the overall process to achieve superior properties of the final parts.

This group covers a broad range of technologies, from classical processing techniques (e.g., injection molding, compression molding, extrusion) to compounding and foaming (physical and chemical). Furthermore, novel technologies (e.g., additive manufacturing) are used to achieve system and function integration of polymers and elastomers. Research work focuses on the flow behavior of polymers, the reduction of process energy and the optimization of the overall process to achieve superior properties of the final parts.

-

Process optimization of rubber injection molding machines

-

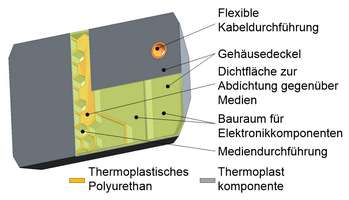

System and function integration of polymers and elastomers

-

Correlation of processing parameter and component behavior (e.g. part quality, mechanical behavior)